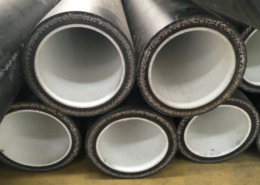

Abrasion Resistant Composite Pipe

Fast abrasion is a common problem for abrasion-resistant pipe when conveying ash, pulverised coal, ore fines, tailings and cements etc. The new abrasion resistant composite pipe has an inner layer made from a developed type of modified polyolefin abrasion-resistant material. The inner abrasion layer greatly improves the abrasion resistance of the pipe during slurry and solid-medium conveying and therefore prolongs the service life of the pipe. Abrasion resistant composite piping, when compared to the traditional ultra-high-molecular-weight PE, has superior abrasion resistance performance and can reduce the mortar abrasion rate by more than ten times. As such, this series of products can be widely used for conveying solids, liquid-solid mixtures, gas powder, slurry and other mediums which may severely corrode the pipes and result in acid, alkaline and salt corrosion.

PERFORMANCE FEATURES OF THE NEW SUPER ABRASION RESISTANT PLASTIC PIPE

Good Corrosion Resistance

With double-sided corrosion resistance performance, it is not only resistant to acid, alkali and chemical corrosion, but can also resist electrochemical corrosion and does not produce the galvanic cell effect with the stray current of the environmental soil. Therefore, it is safe and reliable for conveying solids and liquid mediums that are known to corrode the pipe.

Good Weather Resistance

When used underground, it has the equivalent weather resistance to that of PE pipe and when operating at low temperatures of -40°C, there is no physical property change or frost cracking. It can be used all year round, with no moisture condensation in winter and no need for heat protection of the outer wall in summer (the thermal conductivity is 1/200 of that of steel).

Good Conveying Performance

When compared with traditional pipe, such as steel pipe, this series of pipe has a smoother inner wall without scaling, reduced conveying resistance and better energy saving effects, thereby increasing the conveying capacity between 20-30%.

Easy Installation

Due to its light weight and reduced jointing requirements, it can be easily and quickly installed. It has sufficient capacity to resist underground movement and end load, therefore, expensive anchoring methods normally required for installation are unnecessary. This underground movement & end load resistance means that there is a reduction in the volume of earthworks and trench bedding requirements, thereby reducing overall installation costs.

PN RATING:

PN8 – PN70

SPECIFICATIONS:

DN50 – DN1000

APPLICATION FIELDS:

Chemical Engineering Field

Conveying pulverised coal, ganister sand, salt slurry, potassium salt solutions and alkaline slurry

Mining

Conveying coal water slurry, coal washery sludge, mine filling materials, pulverised mine coal, concentrates and tailings

Coal-Fired Power Plant

Dust removal, slag removal, powder feeding, powder returning and sulfur removal

Metallurgy

Blast furnace coal injection and slag conveying

Cement

Conveying raw material slurry, pulverised coal, finished cement